The time has finally come for us to unveil the exciting new project we have been working on lately! In collaboration with the German auto dealer Autohaus Jakob, Danilift has commenced the production of a new custom project, which will be working in a rather unusual environment: a salt mine.

This unit is the second addition to Danilift's lineup of mining platforms.

You can take a look at our mining platform from 2019 right here:

In June, two of our colleagues went on a trip to Germany to see the salt mine in question and to discuss the creation of a special lift they need: a radar lift. The radar lift is not new to this customer; they use this type of machine in their daily work already. However, their old radar lifts could use the company of a new and improved model, and that is where Danilift comes in—which is new and very exciting to us.

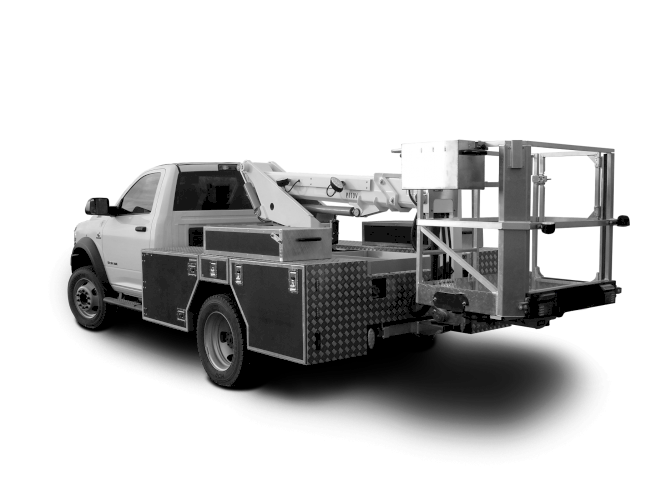

As you may know, making platforms for mining is not new to Danilift per se. In 2019, Danilift developed the P110V mining platform for Palfinger Platforms, which was mounted on a Dodge Ram from Autohaus-Jakob.

This platform is specifically made to work underground because it comes as a self-assembly kit, making it easy to transport into the mine to be assembled down there, and of course it comes with an array of special solutions, allowing the unit to move around with ease in the rough terrain of the mine and keeping the operator safe in this rather special work environment. In addition to the brand-new radar lift, we are also currently working on two more P110V mining platforms for the customer.

The new radar lift is mounted on a Jeep Wrangler, and it sets itself apart from our other products on many more counts than the P110V mining platform does. One of these is that the radar lift is not going to be lifting a man but will instead be lifting radar equipment, which can detect whether there are holes above the ceiling of the mine, for instance. The platform is not telescopic either, it has a fixed boom that only moves up and down, keeping the radar equipment in the right position relative to the surfaces of the floor and the ceiling. In such a challenging work environment, machines like the radar lift and the mining platform are essential to be able to work efficiently

and—most importantly—safely. When our colleagues went to visit the salt mine, they were equipped with all the necessary safety gear and went underground for a little tour and a demonstration of the old radar lift. It was a special experience for the visitors because a modern day mine looks nothing like the dark, dirty, narrow tunnels most of us imagine when we think of mines. It is so huge that it has its own traffic network with long stretches of road, plenty of road signs, and large, well-lit workshops, and the temperature down there is quite high as well – around 30˚!

In our production workshop in Farsø, we have been working on preparing the radar lift. We are very excited to be able to show you the finished product and to tell you much more about what it can do, but until then, here are a few photos of the Jeep in its current state:

Such a cool-looking vehicle! At this first stage, we have started preparing the Jeep to be taken apart before we can assemble and eventually mount the radar lift onto it.

We are proud to be able to deliver custom solutions like this one to customers with special requests, and we are grateful to have the pleasure of collaborating with Autohaus Jakob.

We can’t wait to show you the result!